Pabrik Baterai Tesla

Tesla Bangun Pabrik Baterai Terbesar di Dunia

Produsen mobil listrik Amerika Tesla Motors dan perusahaan Jepang Panasonic Corporation sepakat membangun pabrik baterai terbesar di dunia.

Menurut kesepakatan yang ditandatangani hari Kamis (31/7), pabrik – yang dikenal sebagai Gigafactory – akan dibangun di Amerika dan dikelola oleh Tesla, sedangkan Panasonic akan menyediakan peralatan produksi massal sel lithium-ion. Baterai yang diproduksi akan digunakan dalam mobil listrik yang diproduksi oleh Tesla Motors dan baterai-baterai untuk keperluan lain.

Menurut pandangan Tesla, tingginya harga baterai mobil listrik menghalangi kemajuan mobil-mobil listrik masuk ke pasar yang lebih besar.

Perusahaan itu berharap dapat menurunkan biaya baterai tahan lama dengan mengoptimalkan proses manufaktur dan menempatkan semua aspek produksi di satu tempat.

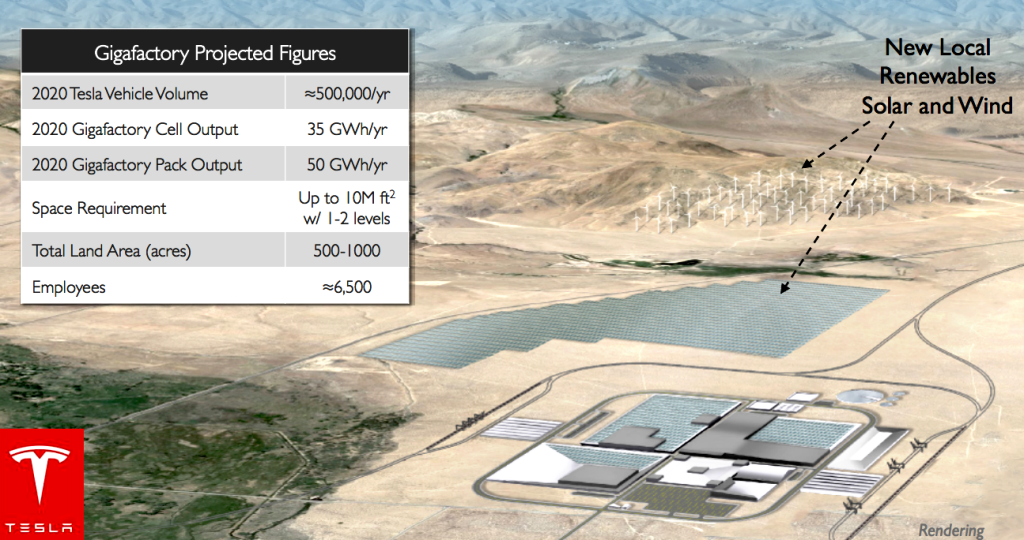

Tesla mengatakan Gigafactory dapat mempekerjakan 6.500 orang menjelang tahun 2020.

Sumber: VOA News

Tesla-Panasonic Battery

=========================

Tesla and Panasonic Agree to Build Factory in U.S.

Tesla Motors announced on Thursday that it had an agreement with Panasonic to build a large-scale battery plant in the United States.

Hours after the deal, the company said its losses grew in the second quarter to nearly $62 million, or 50 cents a share, from $30.5 million in the year-ago quarter. But adjusted earnings were 11 cents a share, 7 cents higher than analysts estimated.

The planned factory will produce batteries for Tesla’s all-electric vehicles, as well as modules for the stationary storage market, according to a news release from Tesla.

The company said it estimated that the plant and its associated supplier complex, which it is calling the Gigafactory, would employ 6,500 people by 2020. The company has not yet said where it will be located and is negotiating with several states.

Panasonic’s 18650 lithium-ion cell for Tesla Model S. On average there are roughly 7,700 cells per one car.

J. B. Straubel, chief technical officer and co-founder of Tesla, said the plant represented “a fundamental change in the way large-scale battery production can be realized.”

“Not only does the Gigafactory enable capacity needed for the Model 3, but it sets the path for a dramatic reduction in the cost of energy storage across a broad range of applications,” Mr. Straubel said in a statement.

The joint project calls for Tesla, which is based in Palo Alto, Calif., to “prepare, provide and manage the land, buildings and utilities” as well as assemble the battery packs. Panasonic will manufacture and supply the lithium-ion cells needed for the batteries and invest in machinery and tools.

The goal, Tesla said, is to reduce costs required to make battery packs for vehicles, which will enable the company “to meet its goal of advancing mass market electric vehicles.” Currently, the large batteries required to power electric cars are a main reason such cars are much more expensive than conventional gas-powered vehicles.

Tesla said those cost reductions would be “driven by economies of scale previously unobtainable in battery cell and pack production.”

Yoshihiko Yamada, Panasonic’s executive vice president, said in a statement on Thursday that once the factory was up and running, the company believed it would be able to “accelerate the expansion of the electric vehicle market.”

So far, the market for electric vehicles has struggled to break through from niche territory. Tesla itself sold only about 1,500 vehicles in June and 9,100 in the first half, according to Autodata. That was up a bit compared with the previous year.

The Nissan Leaf saw fairly impressive growth in the first half of the year, with sales up 29 percent compared with 2013 — though the total number of Leaf sales, 12,736, remained small.

Sales of the Chevrolet Volt, General Motors’ marquee plug-in electric vehicle, have dropped since last year. In the first half of 2014, the Volt’s sales were down 13 percent at 8,615.

For the second quarter, Tesla reported $769.3 million in revenue, below Wall Street’s expectations of $801.9 million. In the year-ago quarter, Tesla lost $30.5 million on revenue of $405.1 million.

Tesla predicted last Friday that it would sell 9,000 cars in the third quarter, and 35,000 for the entire year. The company also told investors it would spend $100 million more in 2014 than previously expected, for expanded production and construction costs related to the Gigafactory.

Source: Aaron M. Kessler / NY Times

=========================

Tesla Giga-Factory

Tesla-Panasonic Battery at CES 2014

=========================

Tesla’s massive battery factory could be a game-changer in many ways

Electric car maker Tesla Motors hasn’t just blazed its own trail when it comes to designing and building a hot electric car. It’s also made breakthroughs in many aspects of the automotive business (the sales channel, the servicing, the over-the-air-software updates) and now it’s doing the same thing for the core part of the electric car: the battery.

This week Tesla revealed more details about its plans to build a massive — the largest of its kind in the world — battery factory in the U.S. that will produce enough lithium-ion batteries by 2020 to outfit 500,000 electric cars. While Tesla only released a few details of the plan, the company said that by 2020 the battery cell output of the factory would be 35 gigawatt hours per year, and battery pack output would be 50 gigawatt hours per year.

Battery Boom

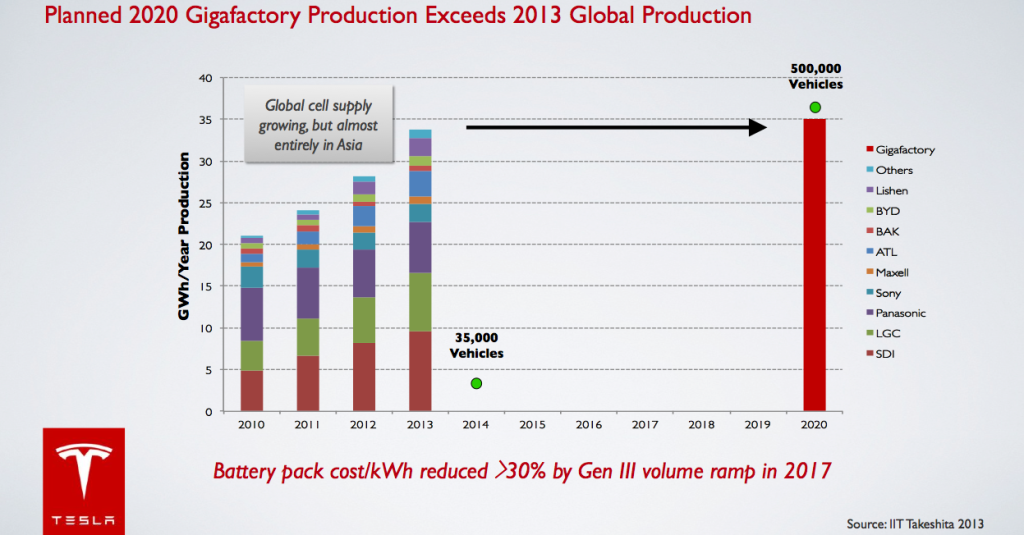

Let’s put these production numbers in perspective. As Tesla has said itself, its cars are constrained by global battery production, and it would need to use all of the batteries produced for electric cars in 2013 (and then some) to make those 500,000 per year by 2020. According to Navigant Research analyst Sam Jaffe, Tesla already used half of all the batteries made for electric cars in the world in 2013 for its Model S car (22,477 cars sold).

Global cell supply growing, but almost entirely in Asia. With Tesla gigafactory, America will catch up cell production by 2020.

In terms of global lithium ion and advanced battery production — beyond just for electric cars — Tesla’s so-called “gigafactory” is still massive; it’s jaw-dropping actually. According to Navigant’s figures, battery factories in the world produced close to 27 gigawatt hours of advanced batteries (the vast majority of these, over 90 percent, are lithium-ion batteries) in 2012. The bulk of those batteries — 23 gigawatt hours — were for consumer electronics, like our laptops and cell phones.

Given Tesla’s production goals outline above, the planned factory would more than double the current entire world’s lithium ion battery production. Of course, global lithium ion battery production would also ramp up outside of Tesla as well, as more gadgets and cell phones are sold and more devices get connected.

And now, if you look beyond just batteries, Tesla’s factory could be the largest factory of any kind, anywhere in the world in terms of inputs in and outputs out, said Jaffe, though he notes that such a thing is pretty hard to measure.

A manufacturing win for the U.S.

The country that made the most advanced batteries in 2012 was China, which produced about 13 gigawatt hours of batteries. Chinese batteries traditionally have been the cheapest in the world, but they’ve also been of lower quality compared to those made in Japan, Korea and the U.S.

However, battery expert and founder and CEO of battery startup GELI, Ryan Wartena, told me that he’s seen the quality of Chinese batteries go up substantially over the past year. Chinese battery giants also have been trying to boost production as well, and Chinese lithium battery manufacturer Thunder Sky Group had been looking to build a battery factory in Russia working with Russian state run agency RUSNANO — this would have been the largest lithium ion battery factory in the world (I’m not sure of the current status of this factory).

The second largest producer of batteries in the world in 2012 was Japan, with about 7 gigawatt hours. South Korea follows with about 2 gigawatt hours. The U.S. had about 1.2 gigawatt hours — and that’s following the attempts of Obama’s stimulus package to boost battery production in the U.S. through companies like A123 Systems and LG Chem.

So as you can see, Tesla’s plans to generate 35 and 50 gigawatt hours per year in cells and packs, just in the U.S., all of a sudden tilts the world’s lithium ion battery production in favor of the U.S., which has never been much of a battery manufacturing powerhouse. No doubt, all of the states in the running — including Arizona, Nevada, Texas and New Mexico — will be vying for those 6,500 jobs.

Tesla’s factory will also be a competitive threat to Chinese battery production dominance and will help lower the overall price of lithium ion batteries globally. “Just the threat of (Tesla CEO) Elon Musk building this huge factory will lower prices,” says Wartena, as the companies will be willing to lower their margins to compete.

Innovative partner approach

Like Tesla has done with many of its strategies, it’s taking a novel approach to working with partners to build the battery factory. Tesla is selling debt (convertible senior notes) to the tune of between $1.6 billion to $1.8 billion to fund part of the battery factory, but Tesla said its partners will likely poney up the extra $2 billion to $3 billion (though, it could be even higher).

Panasonic is Tesla’s chief battery supplier, but in recent months Tesla has also been talking with Samsung SDI for batteries. Traditionally auto makers have multiple suppliers for core components so that they can get the best price and use the other suppliers as leverage.

It should be noted that Tesla hasn’t confirmed that Panasonic is the battery supplier partner for the planned factory. Musk even told Bloomberg that the Panasonic deal wasn’t 100 percent done. Essentially Tesla is keeping its options open for other suppliers to come in and it’s using an unusual way of working with Panasonic. Navigant’s Jaffe called the method “a unique combination of carrot and stick.”

Cheap batteries will change the world

Tesla said that it intends to use some of the battery output for stationary energy storage, which means batteries used for buildings, the grid and even homes. As we’ve reported before, Tesla and solar financier and installer SolarCity (Musk’s other energy company) have been quietly selling small volumes of Tesla batteries as energy storage paired with SolarCity’s solar projects.

If Tesla is able to reduce the cost of lithium ion batteries by a third with its new factory, it could make energy grid storage much more economical. Batteries for the grid — at current prices — are largely too expensive for most projects. There’s a handful of companies that are trying to innovate around using batteries for grid storage, but if Tesla could get the battery price low enough it can potentially disrupt grid storage, too.

Lower-cost lithium-ion batteries could make clean energy much more viable. Pairing battery farms with wind and solar panel farms would enable clean power to store energy when the wind stops blowing and the sun goes down.

The end goal for Tesla is that cheap batteries could help Tesla deliver its $35,000 third generation electric car. It might not be able to get to that price with battery cost reductions alone, but it gets Tesla a whole lot closer.

Source: Katie Fehrenbacher / gigaom