Vertical Farming In Chicago

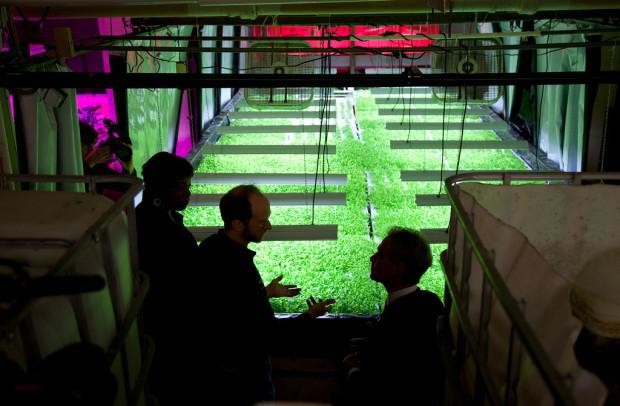

From plant factories fueled by the magenta glow of blue and red LED lights, to the 30-foot tall Ferris wheel for plants in Singapore, we’ve shown you the design possibilities for growing vegetables up instead of out.

But critics ask, what kind of stresses does that put on the plant? And how do you feed this kind of intensive cultivation without spending more than what you get back in the harvest?

An urban farm inside an old meatpacking plant in Chicago is using aquaponics to grow plants and tilapia, but that’s not nearly all. The company is also putting the waste from its operations into an anaerobic digester that will make energy from biogas to fuel the facility.

They say one of the signs of reaching maturity is your ability to answer your critics. Well, vertical farming may be about at that stage.

Our colleagues over at Harvest Public Media report that in Chicago, entrepreneur John Edel is “working hard to show skeptics that garbage itself can fuel vertical farming.” With a grant from the state of Illinois, Edel is “installing a giant anaerobic digester that will convert truckloads of food waste into biogas, burned onsite to keep the lights on,” HPM reports.

The Plant will include a tilapia farm that works in tandem with hydroponic plants to produce food inside the former meatpacking plant.

Edel’s baby is The Plant, a 93,500-square-foot former meatpacking facility in Chicago’s downtrodden Back of the Yards neighborhood. He’s helped transform it into an energy self-sufficient food production operation that will house food nonprofits, for-profits and educational enterprises. Here’s how the website says it works:

“Once completed, the completely enclosed, odorless anaerobic digester will consume 27 tons of food waste a day (nearly 11,000 tons annually), including all of the waste produced in the facility and by food producing businesses all over Chicago. The digester will capture all of the methane from that waste, and the methane will be burned in a combined heat and power system to produce electricity, plus all the process heat needed for an future onsite craft beer brewery. Excess heat will be used to regulate the building’s temperature.”

The “P” from the Peer Food Products sign on the former meat-packing plant has been flipped by the new owners to become the “b” in bEER as “The Plant” develops into a net-zero waste building. The barley leftover from the brewery will become food for tilapia in the indoor

Talk about going off the grid. Among the producers that will benefit from the energy at The Plant are a mushroom farm, an outdoor fruit and vegetable farm, and an aquaponics system raising fish.

Chicago, it seems, is emerging as a hotbed of urban agriculture innovation in the U.S. As we’ve reported, it’s also the home of one of the country’s biggest rooftop farms.

While the digester is still being built, Edel is not shy about his expectations for The Plant. “I think by the end of this year everything will be operational and we’ll be well beyond net zero,” he says.

And with a brewery coming, too, we could drink to that.

=====================================